- E-mail: info@furnace1992.com

- Wechat: +86-13862466658

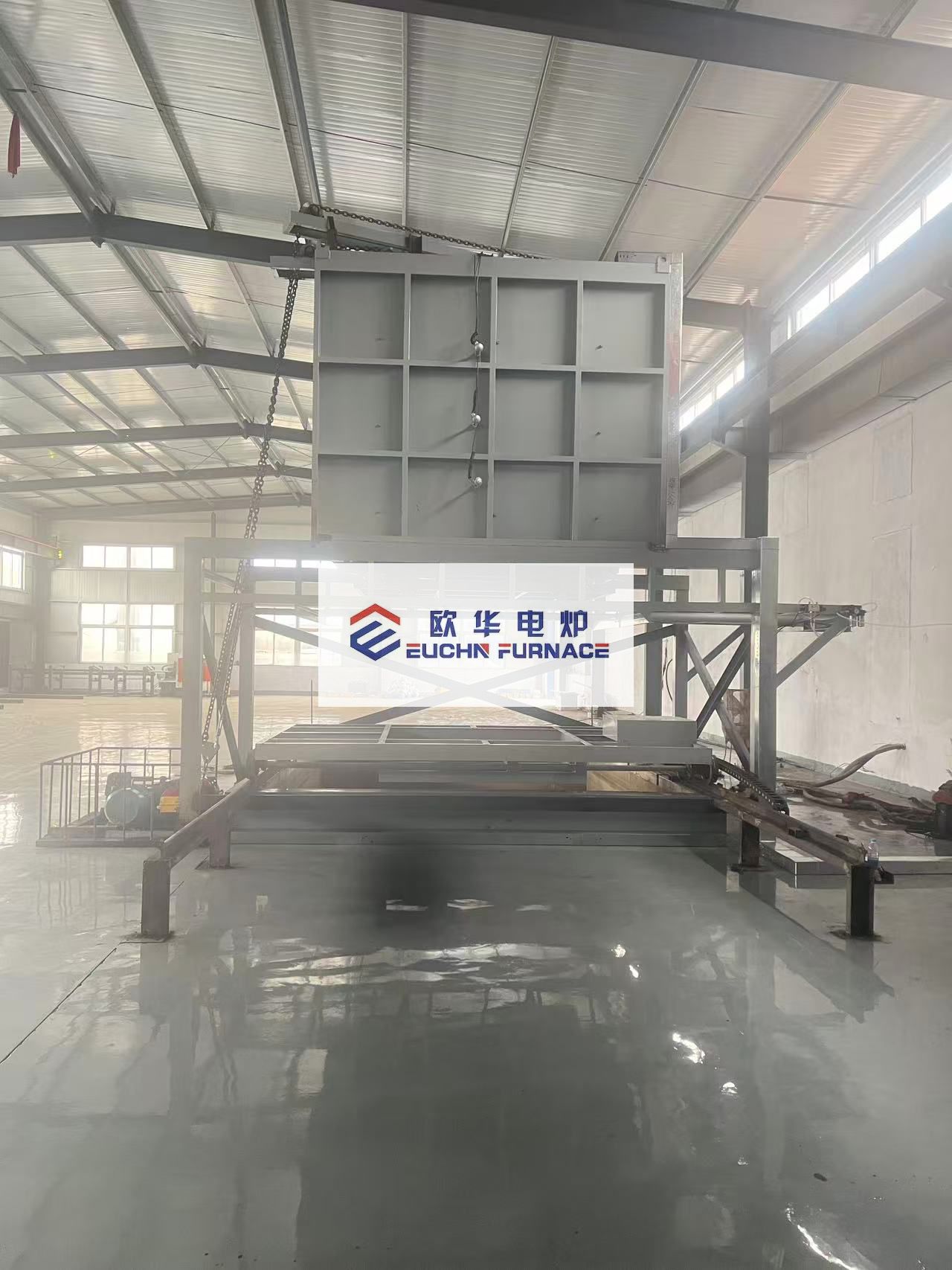

With the widespread application of high-end aluminum alloy materials in aerospace, new energy vehicles, and other fields, vertical aluminum alloy quenching furnaces have become a new focus in the heat treatment industry due to their unique design and technical advantages. This equipment adopts a vertical layout, integrating an intelligent temperature control system with rapid quenching technology, significantly improving the heat treatment quality and production efficiency of aluminum alloy workpieces.

|

No. |

Name |

Technical Parameters |

|

1 |

Rated Working Temperature |

650℃ |

|

2 |

Rated Voltage |

380V |

|

3 |

Temperature Uniformity |

±5℃ |

|

4 |

Temperature Control Accuracy |

Grade 0.3 |

|

5 |

Heating Power |

Resistance band heating 240KW (power adjustable and current limitable), single-zone power 80KW, can be used independently |

|

6 |

Basket Inner Dimensions |

1600 × 1200 × 1200mm |

|

7 |

Loading Capacity |

1000Kg |

|

8 |

Empty Furnace Heating Time |

1.5h (to 550℃) |

|

9 |

Fan Power |

5.5Kw (2 units) |

|

10 |

Furnace Shell Surface Temp. Rise |

≤35℃ (excluding hot spots) |

|

11 |

Quenching Transfer Time |

≤15S |

|

12 |

Quenching Water Tank Effective Volume |

≥30m³ |

|

13 |

Quenching Liquid Temperature |

Room temperature |

|

14 |

Water Tank Heating Method |

Configured as required; not configured for this furnace |

|

15 |

Agitator Power |

Configured as required; not configured for this furnace |

|

16 |

Loading Cart Movement |

Manual push |

|

17 |

Quenching Mechanism Motor Power |

17/11Kw (Descent rope speed: 16/32 meters/min) |

|

18 |

Number of Heating Zones |

3 zones |

Ⅲ.Press Contact

Official website link:www.furnace1992.com

Wechat:+86-13615267218

Whatsapp:+86-13615267218

Email:tina@furnace1992.com

TikTok: HL series drop bottom furnace for aluminum solution heat treatment and vertical quenching