- E-mail: info@furnace1992.com

- Wechat: +86-13862466658

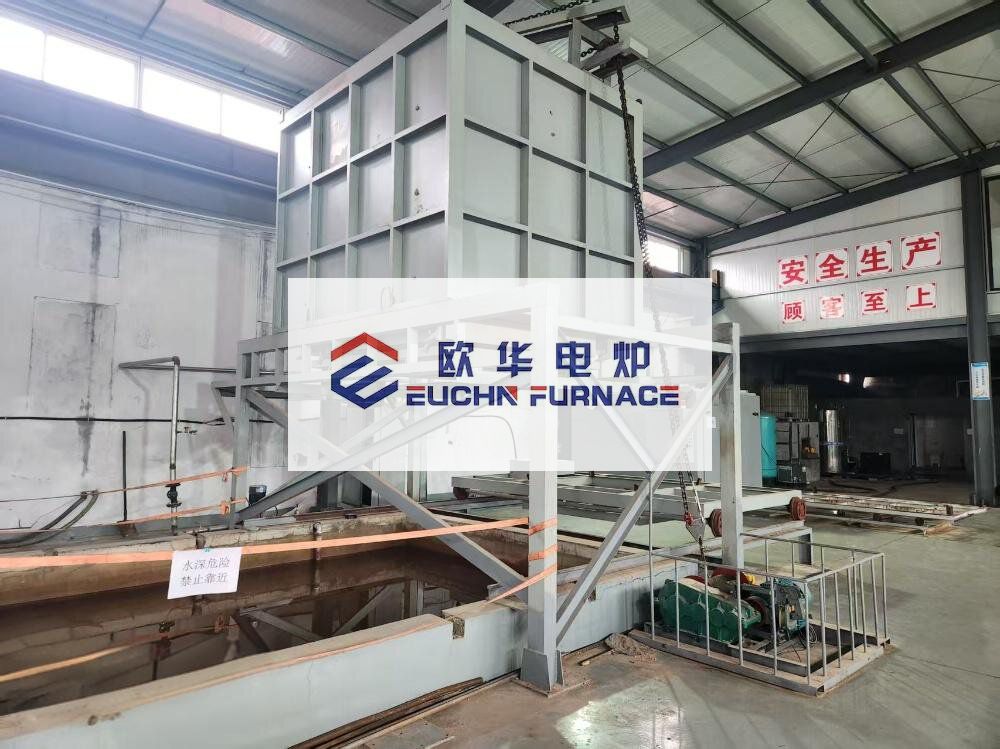

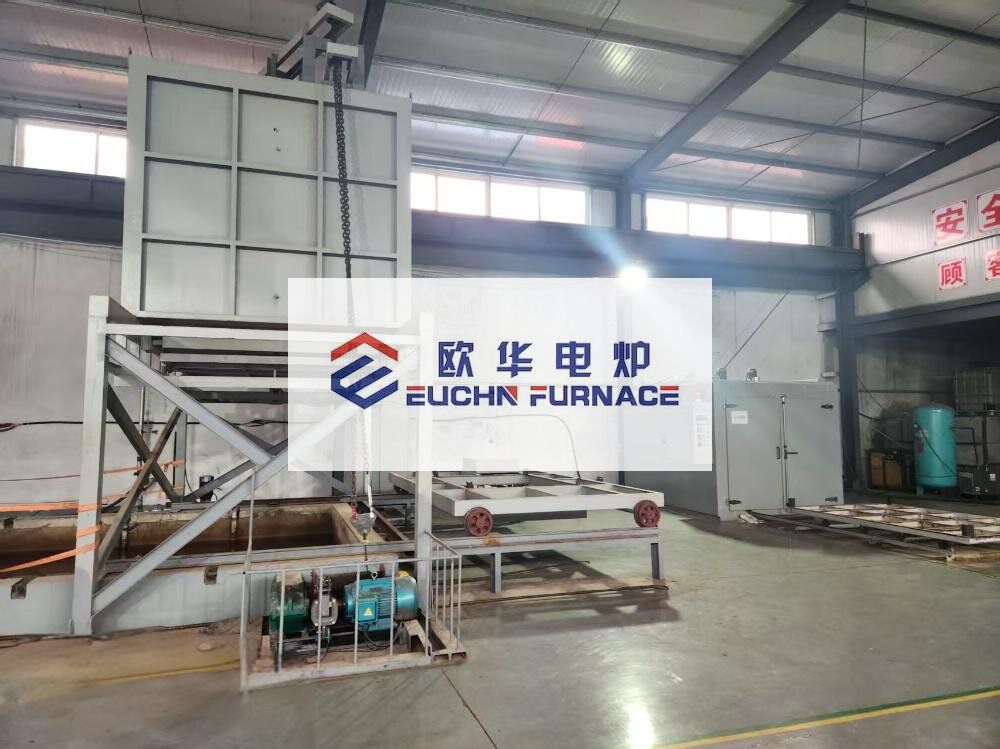

Our company has successfully delivered a Drop Bottom Furnace for Aluminum Solution Heat Treatment and Vertical Quenching, now in operation at our customer’s site.

This advanced furnace is designed for solution heat treatment and vertical quenching process of aluminum alloys.

Key advantages include:

The successful commissioning of this furnace highlights our expertise in heat treatment equipment and helps customers enhance product consistency and production efficiency.

Press Contact: Official website link: www.furnace1992.com

Wechat: +86-13615267218

WhatsApp: +86-13615267218

Email: tina@furnace1992.com

TikTok: HL series drop bottom furnace for aluminum solution heat treatment and vertical quenching